Application

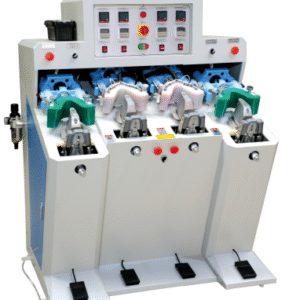

This machine is specifically designed for back part moulding and top-line reshaping in shoe manufacturing.

It ensures perfect alignment between the upper and lining after cutting.

This significantly improves product quality and reduces rejection rates.

Key Features

- PLC Automation

Equipped with a 7-inch color LCD touchscreen.

Displays real-time temperature, time, production capacity, and status.

Operation is intuitive, fast, and highly accurate. - Dual Cooling & Heating System

Independent temperature control for inner and outer molds.

Suitable for various upper and lining materials. - High Efficiency

Rapid cooling system with vaporizer reaching -20°C.

Ensures fast cycle times and high productivity. - Adjustable Clamp Distance

Suitable for different shoe types.

Switchable design enables versatile operation. - Slant Operating Platform

Ergonomic design improves operator convenience.

Reduces fatigue during long shifts. - Custom Mold Design

Tailored molds ensure optimal shaping accuracy.

Delivers consistent results for each shoe model. - Reshape Function

Special mold allows reworking of defective products.

Eliminates wrinkles and maintains top-line appearance. - Environmentally Friendly Cooling

Energy-efficient cooling system.

Enhances performance without compromising sustainability.