Application

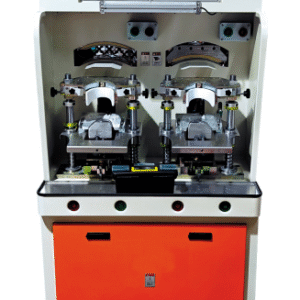

This machine is specifically designed for back part moulding and top-line reshaping in shoe manufacturing.

It ensures perfect alignment between the upper and lining after cutting, significantly improving product quality and reducing rejection rates.

Key Features

• Four-Cooling Four-Heating Module

Large capacity, high production efficiency. Ideal for mass production environments.

• Independent Temperature Control

Temperature of both inner and outer parts of the hot mould can be adjusted separately to meet different heating requirements of various upper and lining materials.

• Tight Adhesion After Moulding

After the back counter pre-moulding process, the upper and lining are tightly and smoothly bonded, ensuring superior quality and lower reject ratio.

• Slant Operating Platform

Ergonomic design enables easier and more convenient operation for the operator.

• Adjustable Clamp Distance

The switch of adjustable clamp can be turned off if not needed, making it suitable for various shoe types.

• Custom Mold Design

Tailored molds based on customer lasts ensure optimal shaping accuracy.

• Reshape Function

Special inverse mould allows reworking of defective products to remove wrinkles and maintain perfect appearance of the topline.

• Dual Compression Units

Uses imported dual compression units; single unit can be selected for light workload to reduce waste and achieve good freezing and shaping effect.

• Environmentally Friendly Cooling System

Uniquely designed cooling system boasts high efficiency and fast cooling performance.

Vaporizer temperature drops to -20°C within 10 minutes of normal operation.