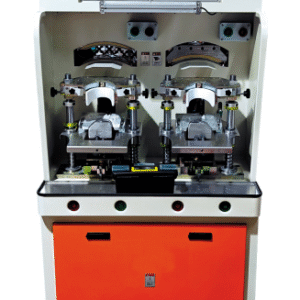

Application

This machine is specifically designed for toe cap moulding in shoe manufacturing.

It enables precise shaping of the toe area before lasting, ensuring better fit and appearance.

Key Features

• Constant Temperature & Steam Softening System

Uses constant temperature control for hot mold heating and a self-made steam softening structure to quickly achieve a softening effect on the upper, resulting in a beautiful shaping effect.

• Adjustable Mold Gap

The gap between upper and lower molds can be adjusted arbitrarily to reduce material surface loss and improve efficiency.

• High-Efficiency Refrigeration System

Features a fast shaping speed for the shoe toe and rapid mold replacement.

Cooling effect is evenly distributed, ensuring stable and consistent shaping results.

• PLC Automation & 7-Inch Touch Screen

Adopts PLC automation control with a 7-inch LCD touchscreen.

Displays real-time temperature, time, production capacity, and status.

Operation is intuitive and fast.

• Intelligent Steam Control

Automatically adjusts steam injection frequency and interval based on material type and softening method.

Improves quality and efficiency through smart vaporization control.

• Multi-Station Operation

Reduces personnel needs, improves production efficiency, and supports high-volume output due to long finalization time.